Fuel remains one of the largest operating expenses for fleet-based businesses; often consuming between 40-60% of total operational costs. In an industry where small inefficiencies add up fast, effective fuel monitoring and full visibility over your fleet’s fuel consumption aren’t just cost-saving measures, they’re key profitability strategies.

At FLEETTRACKER, we equip our clients with tools and insights to run smarter, leaner, and more secure operations. In this article, we’ll explore why fuel monitoring is important, the technologies commonly used today, and the benefits and limitations of each option to help you make an informed decision for your fleet.

Why Is Fuel Monitoring So Important?

Fuel monitoring involves much more than simply tracking liters consumed. In fact, when properly implemented, it helps you:

Without reliable, real-time fuel data, fleet managers are often forced to rely on driver reports and manual logs. Unfortunately, these are prone to errors and manipulation, which ultimately leads to lost revenue and missed opportunities for operational optimization.

Popular Technologies

Modern fleets have access to several fuel monitoring technologies, each with its own strengths and limitations. Let’s break them down:

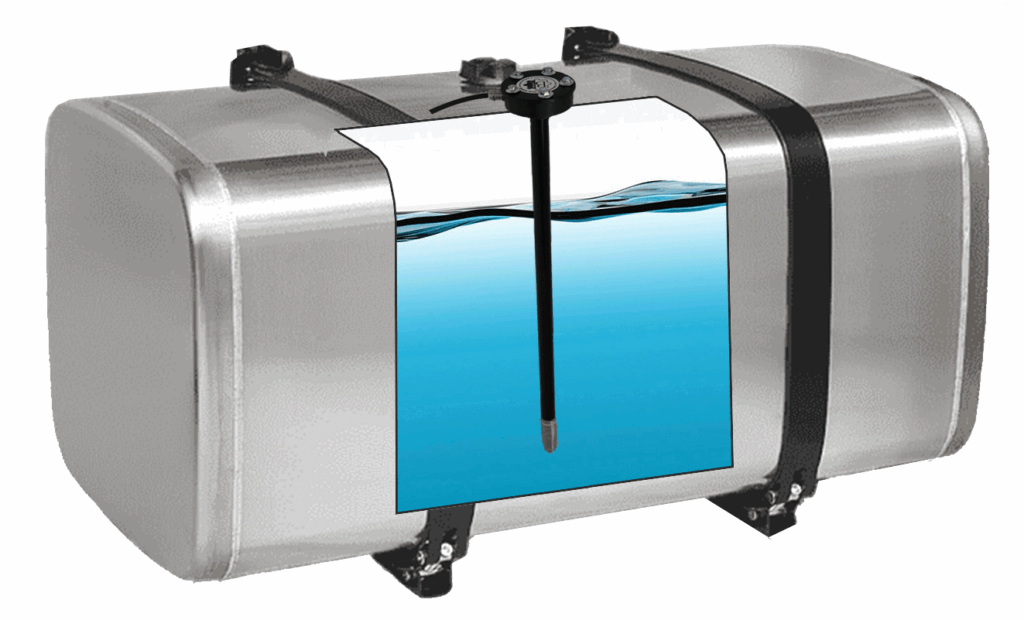

1. Fuel Level Sensors (Capacitive or Ultrasonic Sensors)

How it works:

Installed directly inside or on top of the fuel tank, these sensors continuously measure the fuel level and transmit real-time data to a central fleet management platform.

Benefits:

Limitations:

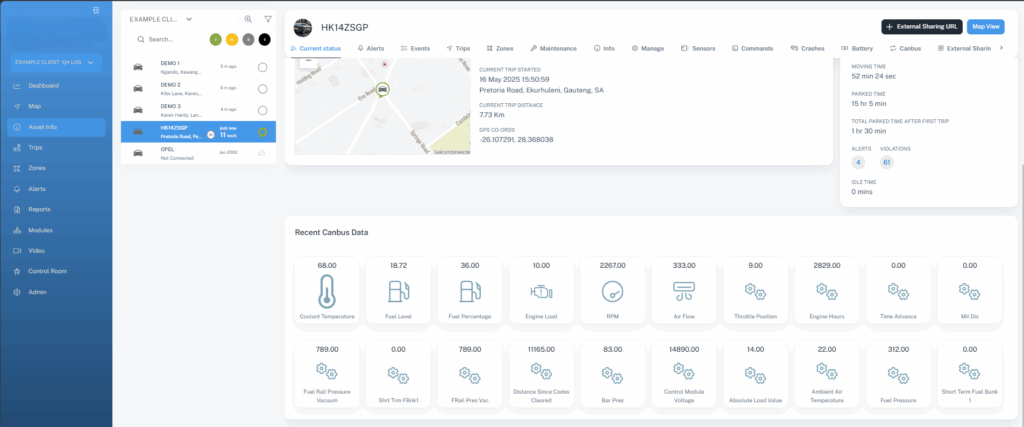

2. OBD (On-Board Diagnostics) / CAN Bus Data Integration

How it works:

Connects to a vehicle’s OBD port or CAN bus system to access engine and fuel consumption data, transmitting it to the fleet management platform.

Benefits:

Limitations:

3. Fuel Gauge Tapping

How it works:

This technique involves connecting a monitoring device to the vehicle’s existing fuel gauge circuit, effectively “tapping” into the sensor signal to estimate fuel levels without installing a separate sensor.

Benefits:

Limitations:

Comparing the Technologies: Summary Table

Which Fuel Monitoring Option Is Right for Your Fleet?

The best choice depends on your:

In many cases, a hybrid approach works best:

Our fleet management system seamlessly integrates with all three solutions, giving you the flexibility to monitor fuel across a diverse fleet from a single dashboard.

Final Thoughts

Fuel monitoring is one of the smartest investments a fleet operator can make to secure operational profits and minimize preventable losses. No matter the size of your fleet, whether it’s 5 vehicles or 500, accurate, reliable fuel data helps you manage one of your most significant operational expenses.

At FLEETTRACKER, we’re here to help you design the most effective, cost-efficient fuel monitoring strategy for your fleet; integrating technology where it makes the most impact.

Let’s Talk

Interested in learning how these fuel monitoring technologies could work for your operation?

Reach out for a free consultation or request a demo of our integrated fuel monitoring solution today.